The following case study describes how SpaceSense 5.3kHz wireless predictive maintenance (PdM) solution gathers high-resolution PdM vibration data from Bluetooth low power sensors while retaining long battery life; and employs Cassia Networks enterprise Bluetooth IoT connectivity to deliver predictive maintenance (PdM) with a high return-on-investment (ROI).

Figure 1 – PdM BoP Solution

As a result, previously underserved markets – Balance of Plant (BoP) components, hard-to-reach machines, and low-cost machines using Run-to-Failure (RTF) maintenance strategies – have a new, cost-effective and high quality PdM IIoT solution for dramatically improving efficiency, uptime, and production profitability.

SITUATION

Many hard-to-reach machines, low-cost machines, and BoP components lack cost-effective, high-quality PdM options. The BoP components in the range of $1k-100k, where a majority of power production takes place, lack PdM because the high-resolution data required for effective monitoring requires the use of a high-cost wired connectivity infrastructure. Moreover, hard-to-reach machines and systems subject to catastrophic failure (such as wind power turbines) are difficult to monitor using manual or wired options due to limited space and structural challenges. For low-cost machines, the cost of deploying a wired PdM solution isn’t justified because RTF maintenance strategies, such as replacing a low-cost machine based on a yearly schedule, have a higher ROI. In other words, wired solutions costs are often too high and the ROI for low-cost machines is too low.

SpaceSense SX3 couples with Cassia’s Bluetooth IIoT for an easily setup, reliable Bluetooth PdM IIoT solution with high “connection density” (one PdM solution connects and monitors many machines), and high-data resolution, resulting in a high ROI for BoP components (Figure 1), hard-to-reach and low-cost machines.

OBSTACLES

Figure 2 – Automated PdM Sampling Scheduling

Compliance guidelines, competition, and bottom line efficiency requirements continue to drive a need for cost-effective PdM vibration data solutions. To meet this need, technicians collect machine data manually by walking to machines based on a schedule using ad hoc, costly wireless access points, like phones or tablets. This inefficient, unreliable manual method also exposes technicians to safety hazards due to the limited range of the ad hoc access points. Moreover, alternative wireless solutions lack the high-resolution data capabilities required for high-quality PdM vibration data monitoring used for many machines, such as BoP components. In many cases, hard-to-reach machines, such as wind power engines, and elevator shaft motors, continue to lack cost-effective PdM options.

ACTIONS

To address the data-quality challenge, SpaceSense uses a Bluetooth low power sensor solution capable of processing high-resolution triaxial data (20khz) at the points of collection. In key production industries, like industrial automation, oil and gas, mining, and power generation, PdM IIoT addresses downtime challenges, and delivers the data needed to reach uptime and efficiency goals, using Sampling Scheduling (Figure 2). Moreover, the SpaceSense solution integrates easily with leading data platforms, including PTC Thingworx, National Instruments, and Siemens MindSphere.

Additionally, when coupled with the reliable connectivity of Cassia’s X1000 long-range Bluetooth routers with a rugged, IP-65 rated enclosures for outdoor or demanding environments, SpaceSense eliminates inefficient and costly manual data collection processes. For hard-to-reach machines – rooftop HVAC, cooling towers, wind turbines, and elevator lifts – the SpaceSense SX3 Bluetooth low power sensors serve as the data collectors. An optional Verizon SX3 Private Network on the Cassia X1000 provides reliable back haul of data. Further, the X1000’s “connection density” provides cost-savings by pairing up to 20 Bluetooth low power devices with each long-range Bluetooth router. As a result, the SpaceSense solution is cost-effective even for low-cost machine environments. Finally, by leveraging the low-cost, low power requirements, and worldwide standardization of Bluetooth, SpaceSense provides a global solution.

RESULTS

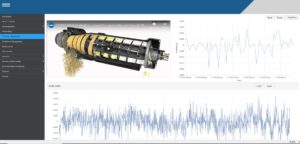

SpaceSense has developed Bluetooth high-resolution IIoT PdM vibration data capabilities while maintaining Bluetooth low power battery life lasting years. Moreover, SpaceSense’s high-resolution 5.3kHz data display (Figure 3) capabilities provide an unrivalled wireless depth of insight compared to alternatives.

Figure 3- SX3 CM Platform Dashboard

When coupled with Cassia’s X1000 reliable enterprise Bluetooth IIoT connectivity, remote management, rugged enclosures, and ease of use SpaceSense’s PdM IIoT is the most cost-effective, high-quality vibration solution for BoP components, low-cost machines replacing RTF strategies, and hard-to-reach machines.