IIoT Whitepaper

Connectivity at Scale: Long-Range Device Communication using Bluetooth for IIoT Condition Monitoring and Predictive Maintenance

INTRODUCTION

The Internet of Things, also known as IoT, is helping industries worldwide become more efficient with managed and scalable digital solutions. More specifically, the Industrial Internet of Things (IIoT) focuses on connecting machines and devices in key industries such as Oil and Gas, Hydropower as well as Manufacturing. In factories, the application of connected sensors to machines are being used to collect valuable data for condition monitoring and predictive maintenance purposes. The goal is to use this data to improve overall operations and make business decisions faster and more accurately. An integral part of condition monitoring is providing data that can be used for predictive maintenance. However, for predictive maintenance to be effective in an industrial setting, the following components are required:

- Machine sensors: data-collecting sensors attached to the equipment for monitoring

- Communication protocol/gateway: a secure, wireless system that allows data to flow between the asset being monitored and a central data repository

- Data repository: a method for which the asset data is stored, processed and analyzed; either on-site or in the cloud

- Predictive analytics tools: advanced algorithms applied to the data to recognize key patterns and generate valuable insights and/or alerts

The idea of using sensors to monitor machines is not particularly new. Factories have been measuring and tracking equipment performance parameters for years, and have evaluated everything from equipment effectiveness, maintenance and overall operations. What’s different about the IIoT is that mass adoption is now possible thanks to the proliferation of smart sensors, the adoption of wireless networking options and the increase of data analytics applications.

Part of the proliferation of smart sensors in IIoT is using Bluetooth Low Energy. Many of us think of Bluetooth as a consumer-oriented technology, but the technology has now been widely leveraged in IIoT. Several reasons for this include low power consumption, low cost, ubiquity, and interoperability.

However, despite its widespread adoption in IIoT, several challenges still remain. This whitepaper will explore the current challenges facing Bluetooth technology in IIoT, possible solutions to overcome these challenges and the benefits of using a long range gateway and centralized management system for Bluetooth to improve scalability, flexibility, security and ease of management.

CURRENT CHALLENGES FACING BLUETOOTH IIOT

In the ongoing effort to improve manufacturing operations and performance, many industrial enterprises have incorporated condition monitoring and predictive maintenance approaches as part of their operations strategy. An important component of this strategy is choosing a wireless protocol. There are many connectivity options to choose from each with its advantages and limitations, but the ubiquity of Bluetooth Low Energy provides a substantial competitive edge.

For industrial enterprises using Bluetooth Low Energy as part of their operations strategy, there were limiting factors that prevented factory personnel from having the real-time visibility needed to mitigate any equipment issues. Below are several Bluetooth technology challenges that industrial enterprises continue to face.

Data collection is a time-consuming process and is not real-time

Most Bluetooth devices are limited by short-range connectivity, therefore, data capture only occurs when someone is physically onsite and within proximity to inspect, monitor and gather data from the equipment. This manual approach to data collection becomes a time-consuming process. Furthermore, during offline hours, valuable data is not being collected in a continuous and automated fashion which can be problematic since the probability of missed failures can be high.

A study conducted by McKinsey & Company states that downtime, whether from repairs, breakdowns, or maintenance, can keep machinery out of use 40 percent of the time or more.

The financial repercussions can damage an organization’s bottom line as well as the negative long-term effects on customer satisfaction.

Limitations with short-range connectivity

The growth of affordable short-range wireless devices using protocols such as Bluetooth Low Energy as well as the rise of IoT gateways has enabled industries worldwide to benefit from lower deployment costs as well as improved operations. However, limitations concerning range and connectivity still exist. Most Bluetooth gateways are limited by short-range and one to one connectivity. In a factory environment with thousands of machines operating simultaneously, there would have to be a substantial number of gateways to provide the necessary coverage.

UNLOCKING THE POTENTIAL OF BLUETOOTH FOR IIOT CONDITION MONITORING AND PREDICTIVE MAINTENANCE

For industries to take full advantage of the capabilities of condition monitoring and predictive maintenance, a comprehensive approach must be considered. The move to a wireless connectivity solution can be complex and involves a wide range of considerations that include redesigning existing business processes, retraining personnel as well as investing in new tools and technologies. However, the benefits of deploying a

more scalable and flexible wireless solution can result in significant cost savings.

Bluetooth technology has evolved and is now recognized by industries worldwide as a cost-effective and flexible wireless solution for several reasons:

Low Power Consumption and Long Battery Life: Compared to Wi-Fi, Bluetooth Low Energy consumes much less power and therefore has a longer battery life. For example, the transmission power of low power Wi- Fi and standard Wi-Fi devices is typically around 11mw to 100mw and the transmission power of Bluetooth Low Energy is typically around 1mw. Consequently, the battery life of a Bluetooth sensor can last much longer compared to the battery life of a Wi-Fi sensor. This is critical for enterprises using wireless sensors that rely on batteries for power.

Significant Cost Savings: Traditionally, enterprises have used a wired solution to solve the connectivity challenge. However, the high costs and complexities associated with rewiring an entire factory and repairing any damaged cables did not yield a positive return on investment, not to mention the extensive planning, money and time required before a wired solution can be fully operational. Furthermore, wired solutions are complex and don’t provide the flexibility needed in industrial environments. For instance, if the layout of the factory changes, the process of re-wiring each sensor is not only very costly, but it is also very time consuming. As a result, many enterprises are looking to Bluetooth technology as a low cost alternative for their wireless solutions.

Another significant cost benefit of Bluetooth technology is the competitive price of its chips and modules. It is estimated that by 2023, nearly 1.6 billion Bluetooth Low Energy devices will ship each year. One reason for this is because of the very low cost a Bluetooth chip and module. The total cost (including supporting components) of a chip and module is much lower compared to other wireless chips and modules, including Wi-Fi.

Interoperability and Ubiquity: Bluetooth protocol is very open. All of the certified Bluetooth devices are guaranteed to interoperate with each other. Tens of thousands of different types of Bluetooth sensors and devices are available on the market today, and are widely used for many different applications. Furthermore, the

2.4GHz unlicensed band in which Bluetooth operates is globally available. Consequently, there is no need to make different types of Bluetooth sensors for each country.

THE IDEAL BLUETOOTH IIOT CONNECTIVITY SOLUTION FOR TODAY’S ENTERPRISES

Device manufacturers and system integrators are often tasked with finding the optimal connectivity solution that will provide the scalability, security, flexibility and reliability while remaining cost-effective. With smart sensors and the right connectivity solution, the ability to monitor equipment improves capacity utilization and factory productivity by avoiding machine breakdowns. Essentially, IoT can transform the legacy maintenance model from one of “repair and replace” to “predict and prevent”.

Cassia Networks works with today’s leading IIoT enterprises to help achieve the optimal connectivity solution to benefit from the advantages of condition monitoring and predictive maintenance. Cassia offers several enterprise Bluetooth gateways designed specifically for various applications as well as an IoT management solution to help device manufacturers and system integrators achieve their business goals. Cassia’s X1000 Bluetooth gateway and IoT Access Controller is very well suited for IIoT. Let’s explore several key features.

First, scalability is essential. When considering the ideal gateway and management platform, device manufacturers and system integrators should consider one that allows for long range and multiple device connectivity. Rather than having machine operators walk near the equipment to gather data, a Bluetooth gateway that is capable of seamlessly connecting multiple devices over a long range will not only improve efficiency, but provide the real-time visibility needed for asset managers to detect machine failure and/or anomalies before it’s too late. Cassia’s X1000 not only extends Bluetooth connectivity up to 1000 feet but it can also pair and connect up to 22 end devices simultaneously and/or listen to hundreds of devices in advertising/broadcast mode providing industrial enterprises with the scalability and flexibility they need.

Cassia X1000 Bluetooth Router

Second, like any other wireless technology, Bluetooth is no exception to security threats especially in a large factory where thousands of assets are being monitored and as connectivity increases. For every asset that’s monitored is another asset vulnerable to security attacks. It’s imperative for organizations to establish strong security protocols as part of their overall business operations. Bluetooth technology employs several layers of data encryption and user authentication measures. For instance, Bluetooth Low Energy uses AES with a 128- bit key length to provide data encryption for enhanced security. Cassia Networks’ X1000 Bluetooth gateway provides advanced AES-128 encryption between a sensor and the gateway to ensure the data is protected. A second security protocol worth mentioning is the Transport Security Layer (TLS). TLS allows devices to communicate over the internet securely without the transmission being vulnerable to attackers. Any communication between Cassia’s X1000 Bluetooth gateway and IoT Access Controller is done through TLS

1.2. This transport security layer is also used between Cassia’s IoT Access Controller and a company’s 3rd party application to ensure the integrity of the data and communication at all times. Cassia’s X1000 and Cassia IoT Access Controller provide these essential security features to provide the real-time visibility needed for end users.

Cassia X1000 Bluetooth RouterThird, when considering a gateway, edge computing should be a priority. Moving processing and analysis to the edge can enable new IoT capabilities such as reduced latency for critical applications. Cassia’s Bluetooth gateways support 3rd party applications running inside a container. This is beneficial for IIoT applications because it reduces latency and cloud costs, and also provides users with better control of end devices. The ability to reduce the network cost of data transmission as well as reducing cloud storage provides a significant cost advantage for enterprises.

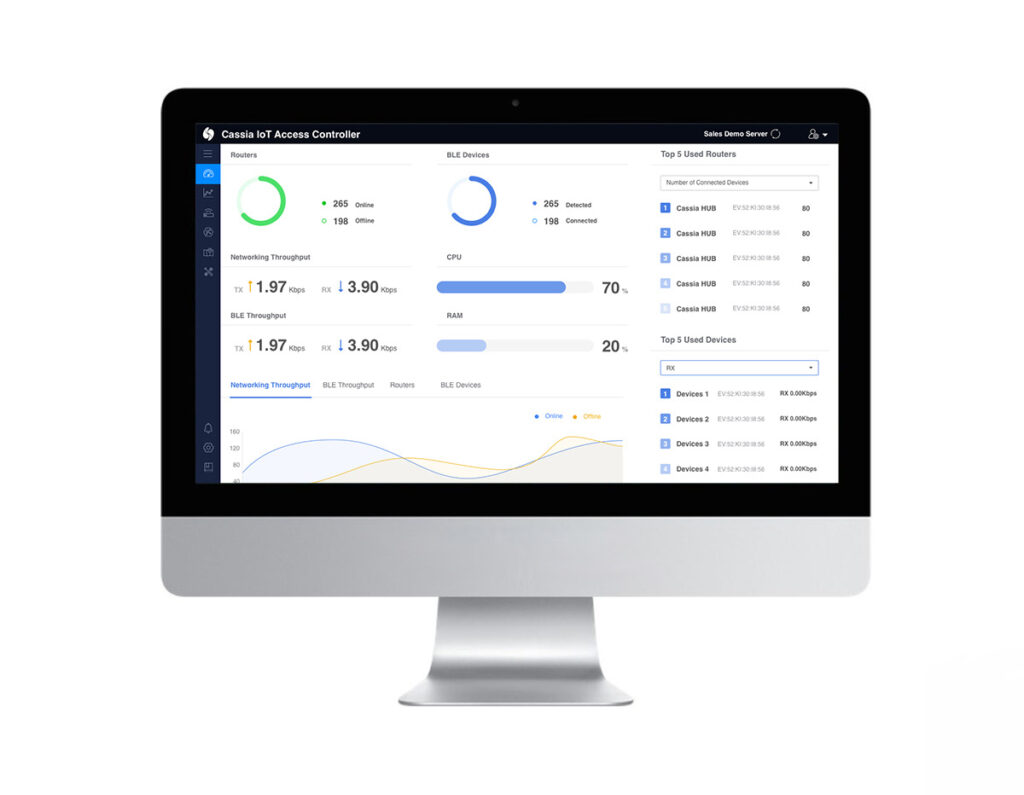

And, in conjunction with the X1000 Bluetooth gateway, Cassia’s IoT Access Controller allows users to easily deploy and manage hundreds of long range Bluetooth gateways and thousands of end devices in an IoT environment from one centralized dashboard, greatly improving scalability and ease of use for IIoT.

Cassia’s IoT Access Controller

Fourth, Cassia’s long range gateways provide the flexibility needed for industrial enterprises. For instance, Cassia’s X1000 Bluetooth gateway supports multiple backhaul options that include Ethernet, 2.4 GHz, Wi- Fi and cellular. This allows end devices to be remotely accessible and controlled via an internet application. Furthermore, cellular connectivity removes the barrier to deployment especially when strict IT policies are in place and must be adhered to. In addition, Cassia’s RESTful APIs allow developers to easily integrate end devices with the X1000 Bluetooth gateway and IoT Access Controller for mobile or cloud applications, as well as a local server. Also, Cassia’s X1000 Bluetooth gateway does not require any changes to existing end devices.

SUMMARY: HELPING YOUR BUSINESS BECOME IIOT READY

To successfully become IoT ready and benefit from the advantages that condition monitoring and predictive maintenance can offer, device manufacturers and system integrators must take a holistic approach when designing the end solution. Key considerations should include sensor selection, the right wireless protocol and gateway as well as a management platform for easy management, analysis and data security.

By choosing the right Bluetooth gateway and management platform as part of this solution, Industrial enterprises can reap the rewards of reduced costs as well as greater operational efficiency and scalability. As the opportunities in IoT for condition monitoring and predictive maintenance continue to evolve, Cassia Networks can be a trusted partner to help your organization take full advantage of these opportunities by helping you choose the right Bluetooth gateway for your business needs.

ABOUT CASSIA

Cassia Networks is the leading provider for enterprise Bluetooth IoT products and solutions. Our patented technology provides the most reliable and easy to manage long-range, multiple device connectivity, edge processing and locationing for Bluetooth IoT networks.

Our mission is to solve the IoT connectivity, locationing and management challenges faced by today’s enterprises and make IoT easy.

To learn more about Cassia’s products and solutions, please visit www.cassianetworks.com or contact us at sales@cassianetworks.com / support@cassianetworks.com.