IIoT Case Study

SpaceSense Systems Delivers High- Resolution Vibration Data for Predictive Maintenance and Condition Monitoring with Cassia Networks

THE CUSTOMER

Headquartered in Greensboro, NC, SpaceSense Systems is a leader in wireless predictive maintenance and condition monitoring solutions for IIoT (Industrial Internet of Things). The company’s vibration sensor is revolutionizing the way industrial organizations monitor the health of their motors and equipment. For years, SpaceSense has been helping organizations worldwide improve production efficiency, minimize equipment downtime and achieve greater cost savings.

OVERVIEW

Many industrial enterprises equipped with hard-to-reach machines such as turbines, cooling towers as well as plant factories with balance of plant (BOP) components often lack a cost-effective predictive maintenance (PdM) solution to effectively monitor the condition of these assets. With complex machines designed to manage and regulate the rest of the plant to ensure reliable and efficient power, these machines must operate at optimal capacity. Implementing a cost-effective predictive maintenance solution has traditionally been a challenge since it required a costly wired connectivity infrastructure.

Second, it becomes increasingly challenging to monitor hard-to-reach machines as well as machines operating in harsh environments. Third, the cost of deploying an expensive wired PdM solution isn’t justified for low- cost machines that could be easily replaced without the unnecessary expense. Fourth, many wireless sensors available (until the SX3 Sensor and communication device) are low vibration resolution between 0.5 and 2kHz compared to the SX3 Samples at 20kHz which wirelessly provide 90,000 points of data across X, Y, Z axis + temperature over a six second sample.

Moreover, the SX3 Sensor can achieve a battery life of up to three years. This level of wireless data is very difficult to achieve over Bluetooth Low Energy (BLE) without affecting battery life. However, this problem has now been resolved with the SX3 onboard power management solution. Last, manual inspection that requires onsite personnel to walk near the equipment (including those in hard to reach and/or dangerous areas) to gather relevant data is not only costly, but also places the worker’s safety at risk.

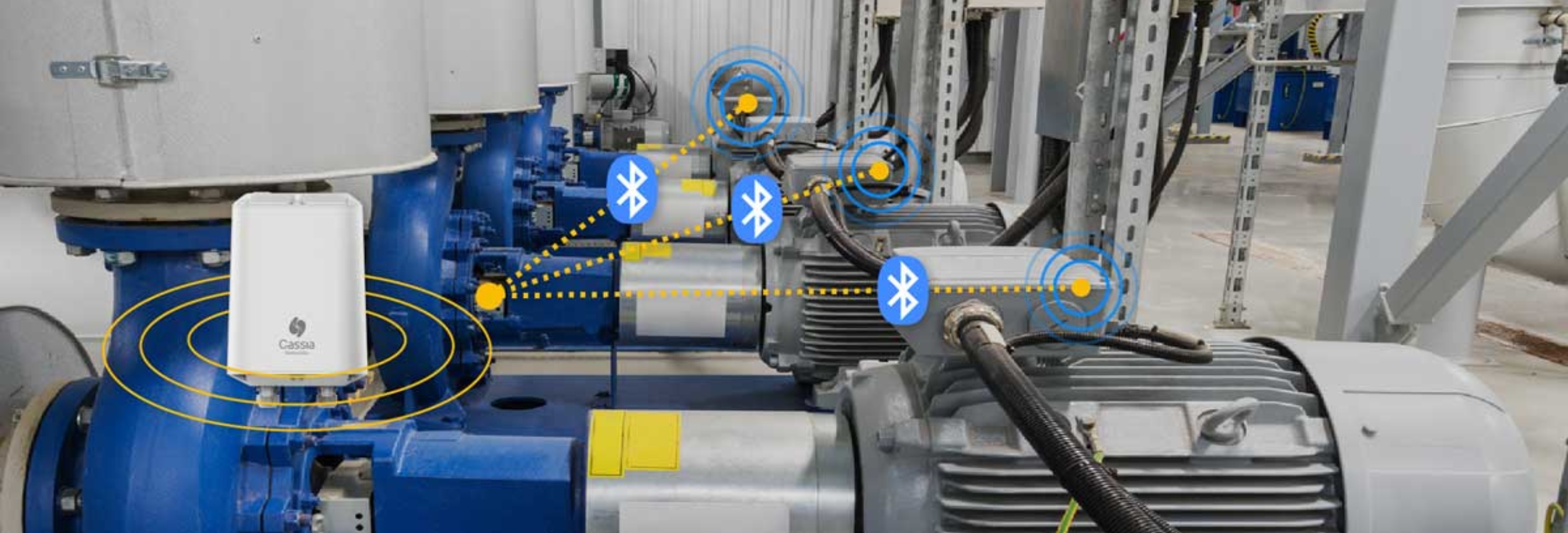

To help industrial enterprises overcome these challenges, SpaceSense Systems’ designed the SX3, a triaxial BLE wireless vibration sensor and a communication tag.

This sensor is attached to equipment such as motors and bearings and is primarily used for gathering high-resolution vibration data for predictive maintenance and condition monitoring purposes. Furthermore, the SpaceSense’s solution integrates easily with leading data platforms, including PTC Thingworx, National Instruments, Siemens MindSphere and other reliability solutions. By gathering high-resolution vibration data and providing autonomous monitoring of equipment, factory personnel can analyze baseline trends of their equip- ment as well as detect and prevent machine failure. For hard-to-reach machines, BoP components and low- cost machines using Run-to-Failure (RTF) maintenance strategies, the company provides a highly reliable PdM IIoT solution to improve efficiency, minimize downtime and achieve significant cost savings. Lower kHz sensors only provide a small glimpse into the overall health of the machine and lack the level of data analysis that can be achieved by the high resolution capabilities of the SX3.

CHALLENGES

After successfully launching their vibration sensor and cloud solution, SpaceSense Systems was faced with the challenge of finding the right gateway and management solution that could meet the specific requirements for industrial environments. They needed a flexible, scalable and reliable wireless solution to address the key challenges of cost and connectivity. Furthermore, the company needed a long-range gateway that was capable of connecting to multiple BLE sensors to enable seamless data transfer, provide reliable connectivity as well as track the location of the equipment. Also, they wanted an easy to use management solution to support 3rd party applications and provide edge processing capabilities. For SpaceSense, data quality, scalability and reliability are essential requirements to provide their customers with an advanced wireless solution that solves the connectivity challenge.

The company’s goal is to ensure that its BLE sensors and tags are meeting the needs of their customers while still remaining cost-effective. It was clear that Space- Sense Systems needed an experienced partner that would deliver a best in class wireless connectivity solution to meet their needs.

SOLUTION

After evaluating other wireless technology options, the company discovered a unique opportunity with Cassia Networks that would allow them to deliver an advanced wireless solution for its customers.

Long Range, Multiple Device Connectivity: Space- Sense Systems chose Cassia’s X1000 Bluetooth gateway to provide the seamless connectivity needed for its SX3 BLE sensors. Because these wireless sensors are attached to thousands of machines dispersed in large factories, the need for a long-range BLE gateway was critical. The company selected Cassia’s X1000 Bluetooth gateway because of the ability to provide long-range connectivity up to 1000 feet in an industrial environment.

Advanced Edge Processing Capabilities: Choosing a technology-agnostic partner like Cassia Networks was a key requirement for SpaceSense. The company selected Cassia’s X1000 Bluetooth gateway because of the ability to support further onboard processing at the mid-edge and to support 3rd party applications running inside the gateway. Not only does this reduce latency and cloud costs, but it also allows for customized control and better data management. Also, SpaceSense uses Cassia’s IoT Access Controller as a hybrid device status and deploy- ment tool to easily and remotely manage hundreds of Bluetooth routers and end devices from one centralized dashboard as well as integrating it with the SX3 IIoT platform. The combination of these technologies allows for additional integrations into 3rd party reliability and asset management systems.

Scalable, Flexible, Easy to Use: Cassia Networks has provided SpaceSense Systems’ customers with a flexible, reliable wireless solution allowing them to deploy at scale. Furthermore, the company needed a partner that would deliver a low-power, low-cost wireless alternative.

Cassia’s X1000 Bluetooth gateway easily deploys end devices and integrates the data from Cassia’s IoT AC using API’s into SX3 IIoT Enterprise System to enable remote management of BLE end devices. SpaceSense’s customers can now reliably monitor machines without the need for onsite manual inspection. Cassia’s easy to use IoT AC provides their customers the ability to manage the status and deployment of hundreds of Bluetooth gateways and to monitor thousands of connected devices in an industrial environment from a rule connected solution through the SX3 centralized platform.

BENEFITS

By leveraging Cassia’s X1000 Bluetooth gateway and IoT AC, SpaceSense has been able to successfully deliver their SX3 Vibration Sensor solution to hundreds of customers worldwide. As a result, customers can now benefit from the following:

Significant Cost Savings: By addressing equipment downtime issues, SpaceSense customers have im- proved the overall efficiency of assets and reduced operational costs associated with repairing and/or replacing expensive machines, extending the life of equipment. By providing end-users with reliable data and autonomous monitoring, factory personnel can accurately monitor the health of their assets and take corrective action to prevent equipment issues and avoid a costly factory shut- down.

In addition to improved cost savings, SpaceSense customers have reduced overall employee health and safety costs. For hard to reach machines and hazardous environments, employee health and safety is always a concern.

The combination of SpaceSense’s SX3 vibration sensor, Enterprise IIoT solution, Cassia’s IP65 certified X1000 Bluetooth gateways and IoT AC allow factory personnel to remotely monitor machine health minimizing the need for physical inspection in harsh factory environments.

Accurate Data and Analytics: To address the data-quality challenge, the company uses a Bluetooth low power sensor solution capable of processing high-resolution triaxial data (20kHz) at the points of collection. However, receiving accurate data from the equipment was one of the biggest challenges for SpaceSense and its customers, especially BoP components and hard to reach machines. Cassia’s X1000 Bluetooth gateways are being used in conjunction with the SX3 vibration sensors and Enterprise IIoT solution to seamlessly transfer data between the sensor and the internet to provide custom- ers with the valuable data they need to detect any faulty equipment. This allows customers to take corrective action to optimize machine performance and reduce long term operational costs.

Improved Customer Satisfaction: SpaceSense Systems is a company known for providing exceptional customer service. After partnering with Cassia Net- works, the company now delivers a flexible and scalable wireless solution for its customers. In addition to improving overall customer satisfaction and loyalty, SpaceSense customers now benefit from improved cost-savings, reduced occupational health costs and a greater ROI.

Cassia Networks values the partnership with Space- Sense and remains committed to its ongoing developments and those of its customers. Over the years, Cassia has become a trusted partner for the company as they continue to focus on scaling their Enterprise IIoT solution to meet the ongoing needs of its customers resulting in the successful deployment of the SX3 Vibration Sensor in hundreds of IoT environments worldwide.

With Cassia’s X1000 Bluetooth gateway and IoT Access Controller, SX3 provides our customers a flexible and scalable solution for monitoring the condition of assets resulting in reduced downtime and greater cost savings. Cassia has been instrumental in the success of SX3 and the SX3 Enterprise IIoT platform. They have been very supportive and collaborative in upgrading and making enhancements to their long-range gateway device, to meet the needs of the SX3 and that of our customers.

ABOUT CASSIA

Cassia Networks is the leading provider for enterprise Bluetooth IoT products and solutions. Our patented technology provides the most reliable and easy to manage long-range, multiple device connectivity, edge processing and locationing for Bluetooth IoT networks.

Our mission is to solve the IoT connectivity, locationing and management challenges faced by today’s enterprises and make IoT easy.

To learn more about Cassia’s products and solutions, please visit www.cassianetworks.com or contact us at sales@cassianetworks.com / support@cassianetworks.com.